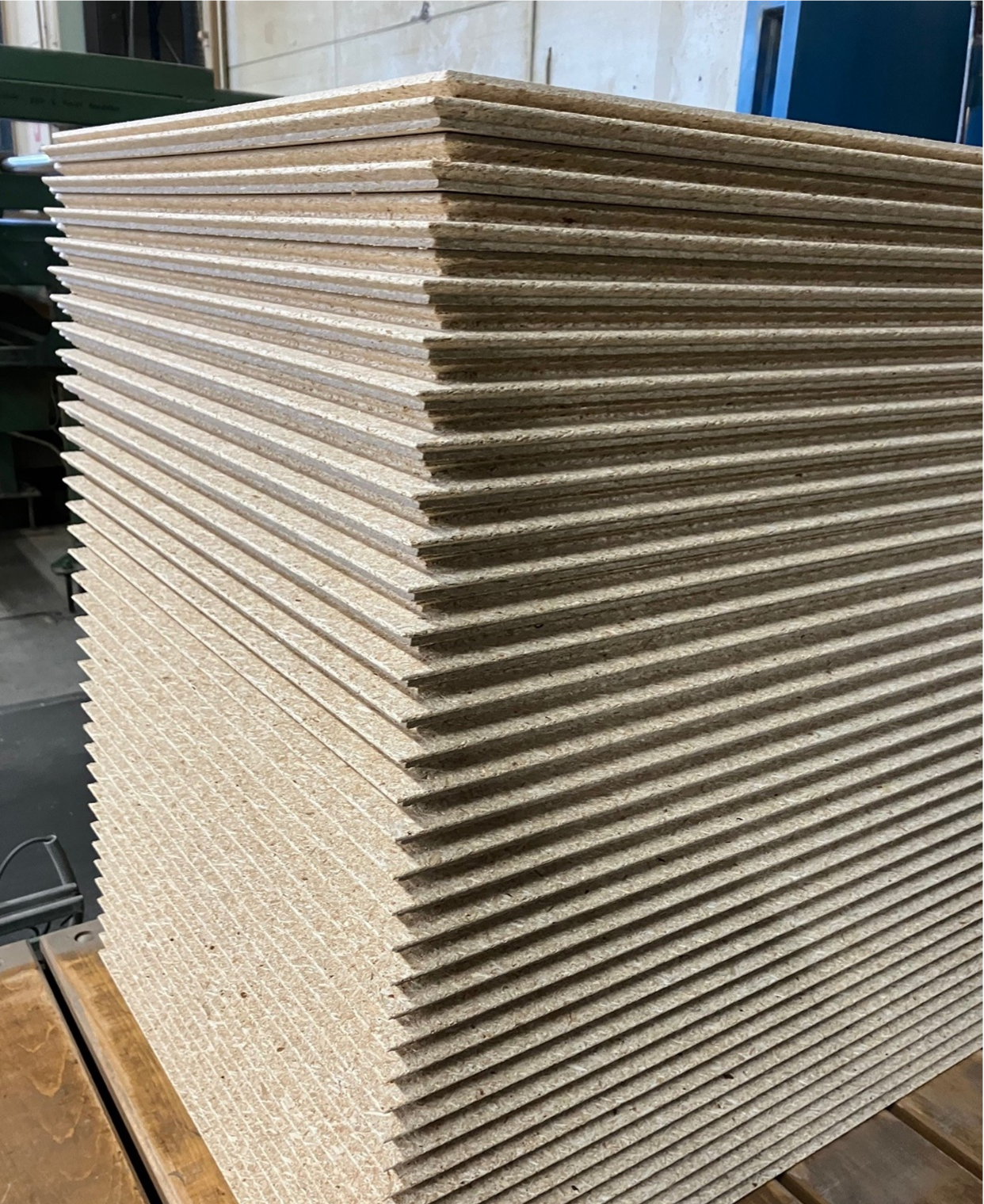

Eco Materials develops technology and production processes to create an industrial advantage in material recycling. Together with our partners, we design and set up complete recycling facilities, including inbound and outbound logistics. Our production is data-driven and highly automated.

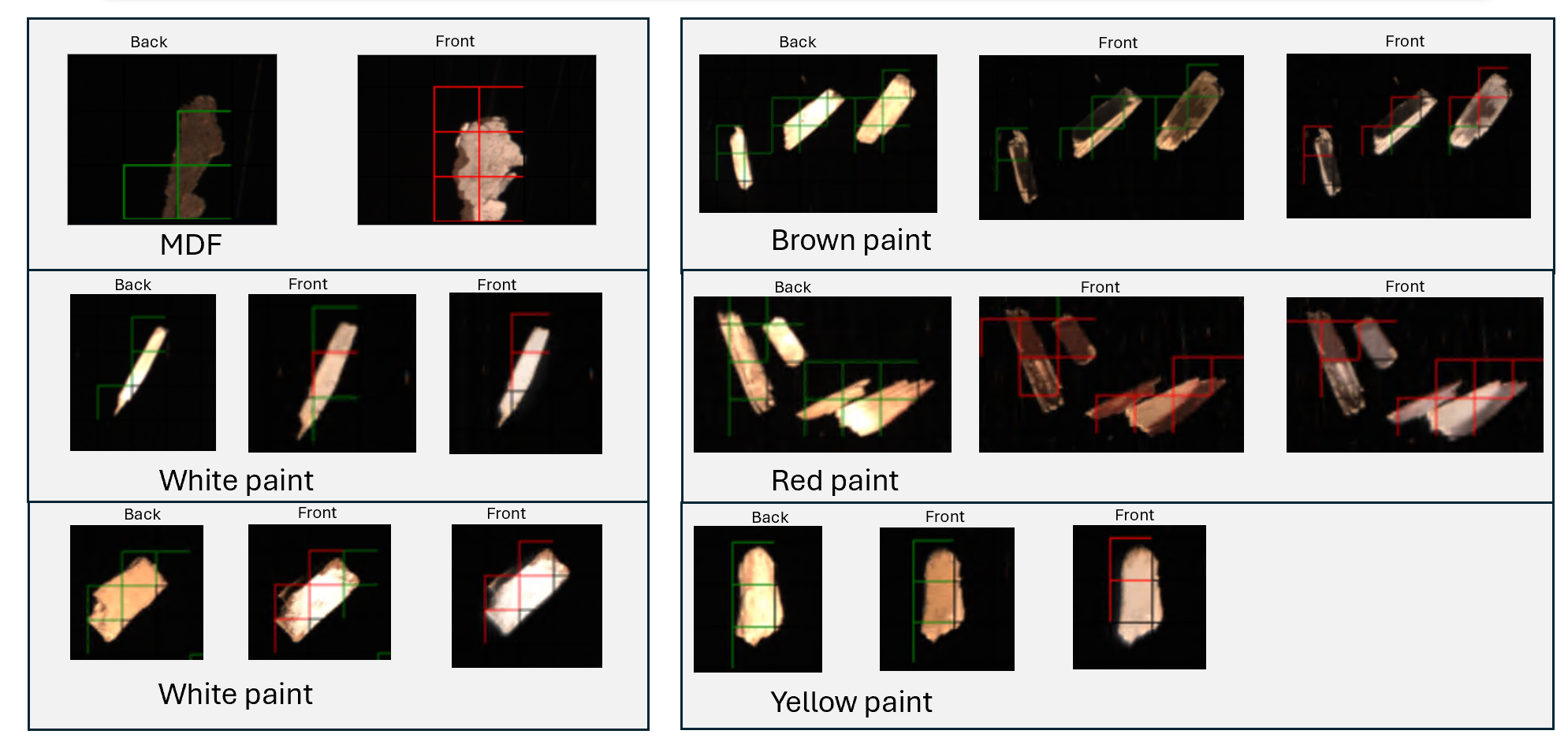

Sorting systems – we produce and deliver machines with AI-optimized sorting, and solutions for removing metals and dust. We have built our own AI architecture that allows for rapid development and implementation of new sorting models. We have sorting models for waste wood ready for implementation, but we can also deliver sorting models for other materials.

Automation – we design and deliver fully automated sorting lines, either by combining our sorting systems with existing machinery, or a complete new sorting line.

Change Management – our team has decades of experience in advisory and project management related to implementing new technology. We help customers with the transition from waste reduction to material recovery since this change is as much about changing organizational mindset as implementing new technology